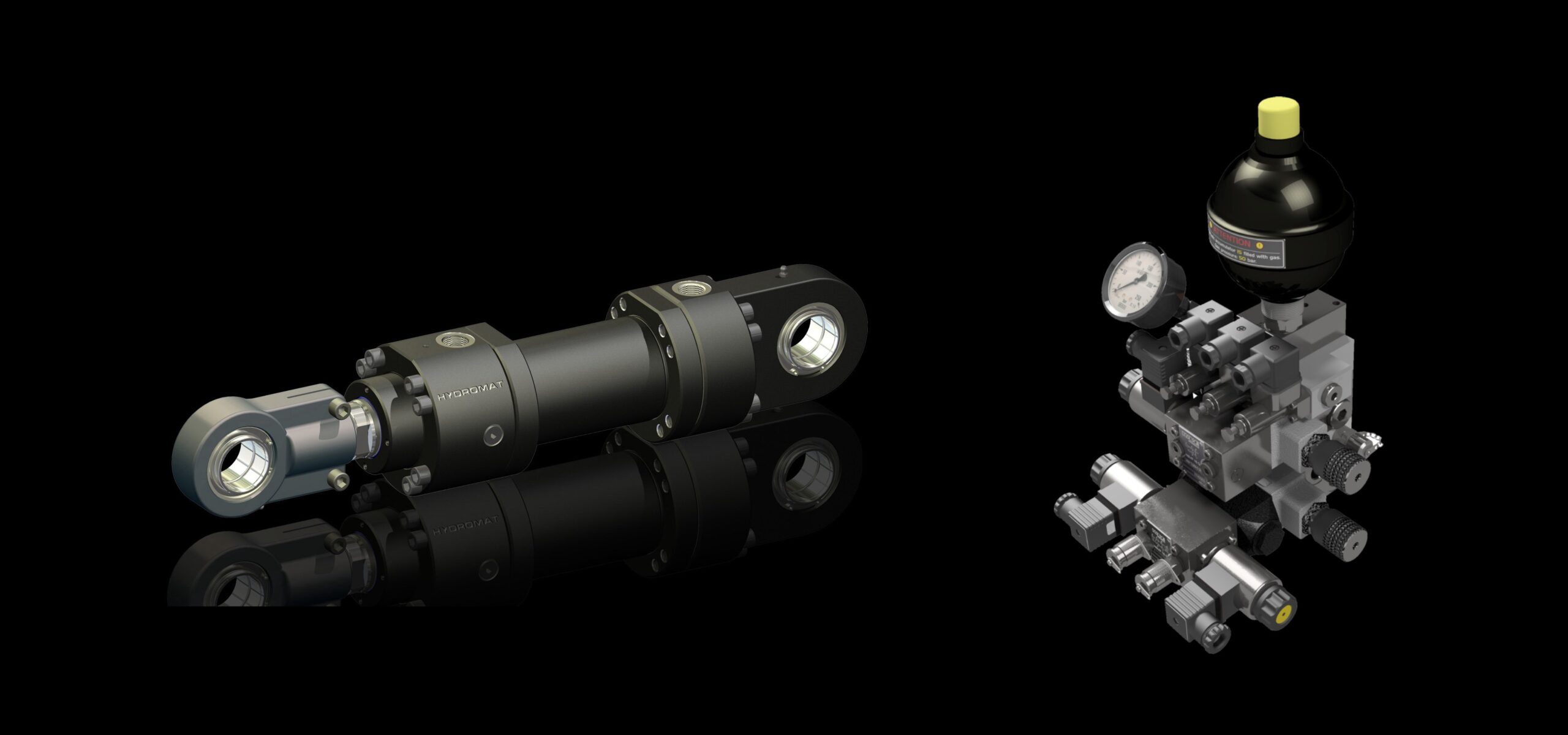

CHECK VALVES AND SHOCK ABSORBER SYSTEMS

Check valves are the key element in prevention of back flow and water hammer that can damage pumps and pipeline installations.

Generally, if the back flow reaches to check valve before the valve disc is closed, the result will be slamming in the valve closing and water hammer. Because of this hydraulic shock absorbers need to be installed .

Reverse flow has it’s own static and dynamic component. The absolute size of static and dynamic back flow pressure and nominal size of the pipeline is determined by the damping energy, which must absorb the damping units when the reverse flow occurres. Thus, back flow energy determines the design and size of check valves, damping characteristics, number and position of damping units.

For the check valve design with disc and flaps, HYDROMAT offers different types of damping units and shock absorbers for check valves and system protection against back pressure and water hammer.

Check valves are places of enormous flow losses, which means great financial losses. In that sense, HYDROMAT offers automated damping units that eliminate losses caused by this.

IMPORTANT

On customer request HYDROMAT offers complete equipment which means even the check valves from different producers can be equipped with our damping system.